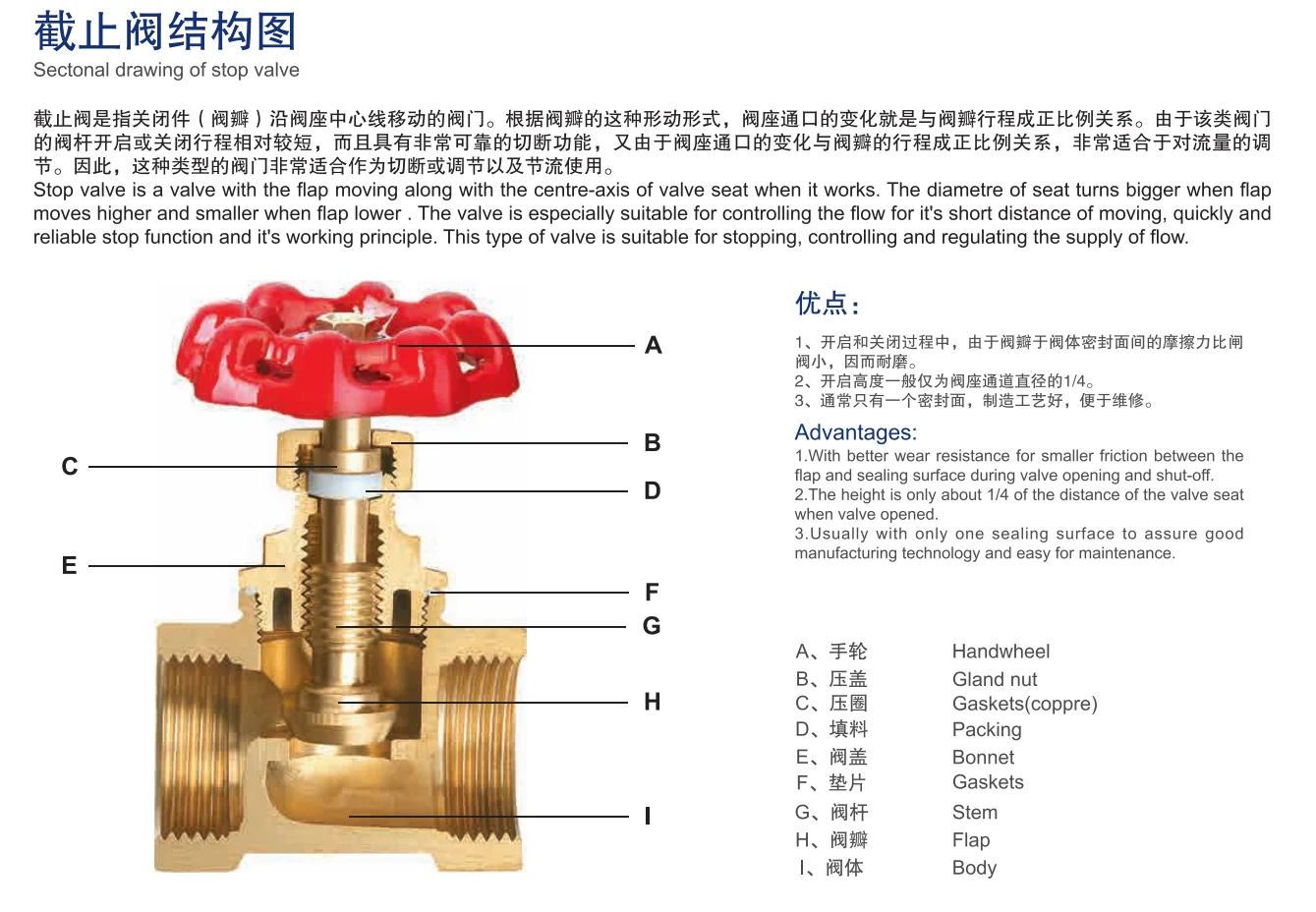

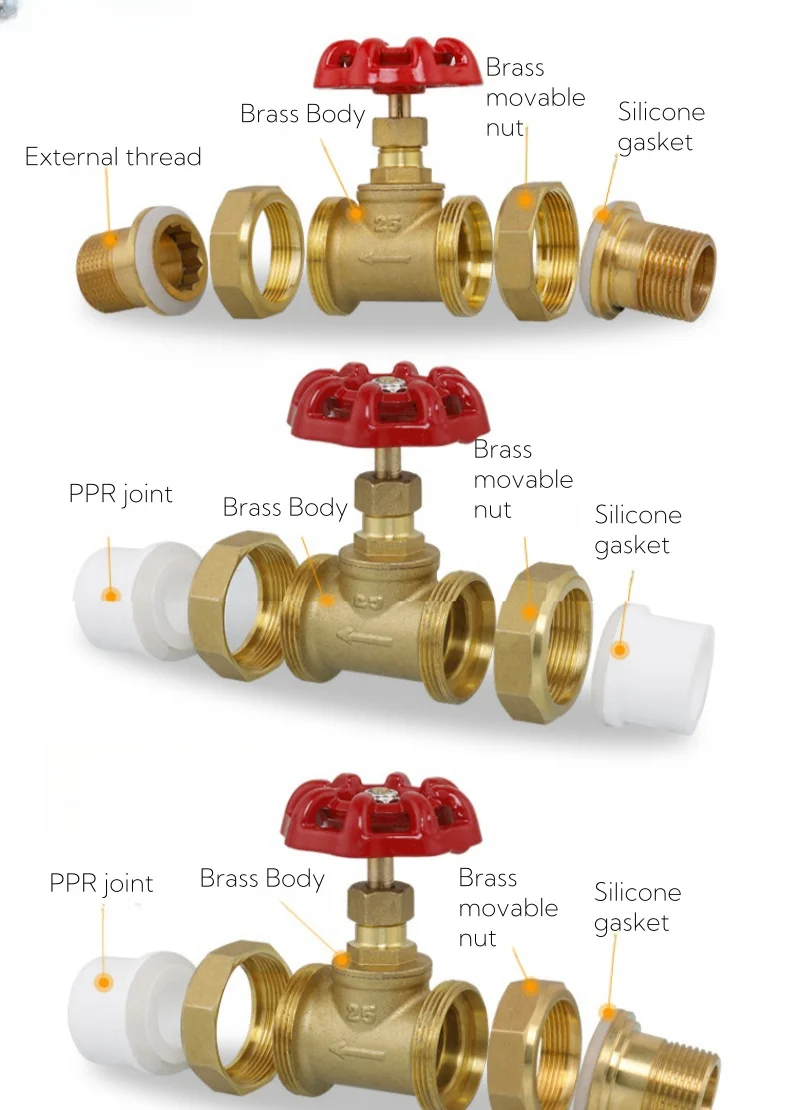

1. The globe valve is a part in the pipeline system that drives the valve disc by rotating the hand wheel to move vertically along the center line of the seat to cut off the control flow regulation. When working, the disc and the valve body sealing surface sound friction force is small, the opening and closing torque is small, resistant, the opening height is generally 1/4 of the diameter of the valve seat, only one sealing surface is easy to maintain, and the medium flow is one-way. The globe valves are all metal sealed valves, which are widely used in central air conditioning and HVAC systems. 2. The stop valve has internal and external thread, sleeve, flange, hot melt connection form. The shell adopts the constant temperature hot forging tempering process, and the inspection is based on the strict implementation of GB/T8464-2008 "iron and copper threaded connection valve" standard, and 100% pressure test is qualified before leaving the factory.

3. The installation of the valve must be carried out by professionals with relevant qualifications. The coaxial deviation of the pipes at both ends should not be too large, otherwise excessive pipeline installation stress will be generated, resulting in failure and damage. The accuracy and effective length of the pipe thread shall strictly comply with the ISO228 standard. The hexagonal or octagonal part of the other end of the valve should not be pulled to avoid deformation of the valve, and must be sealed with polytetrafluoroethylene raw material tape or thread sealing glue.

4. To install the tightening valve, the corresponding torque wrench or pipe wrench must be selected, and the effective thread length can be screwed in. Do not overdo it to cause the top pressure on the inner end face, resulting in damage and leakage of the sealing surface. In order to ensure the normal use of the valve, install filters at the inlet of the pipeline as far as possible.

5. The globe valve handwheel is designed according to the corresponding torque, the size is different, do not use to increase the force arm instead, so as not to damage the valve, the valve stem sealing packing are PTFE, such as abrasion leakage can be tightened cover to compensate the packing. Replace the filler to remove the medium pressure, refrigeration, HVAC system valve must use 1.6MPa(or above nominal pressure) specifications valve.

6. When installing flanged globe valves, ensure that the flanges at both ends of the pipeline are parallel and coaxial, the spacing size is appropriate, and the connecting screw holes are corresponding, and the deviation should not be too large, otherwise the installation quality and sealing performance of the valve will be affected.